About our

• International quality standards certified manufacturing factories located in Malaysia and China

• We are an engineering company creating value-added services to multinational and OEM clients

• Dedicated organizational structure, from Sales/Program, Engineering, Material Planning, Production, Supply Chain, Quality Control, Logistic & Warehouses, HR/Admin to Finance department.

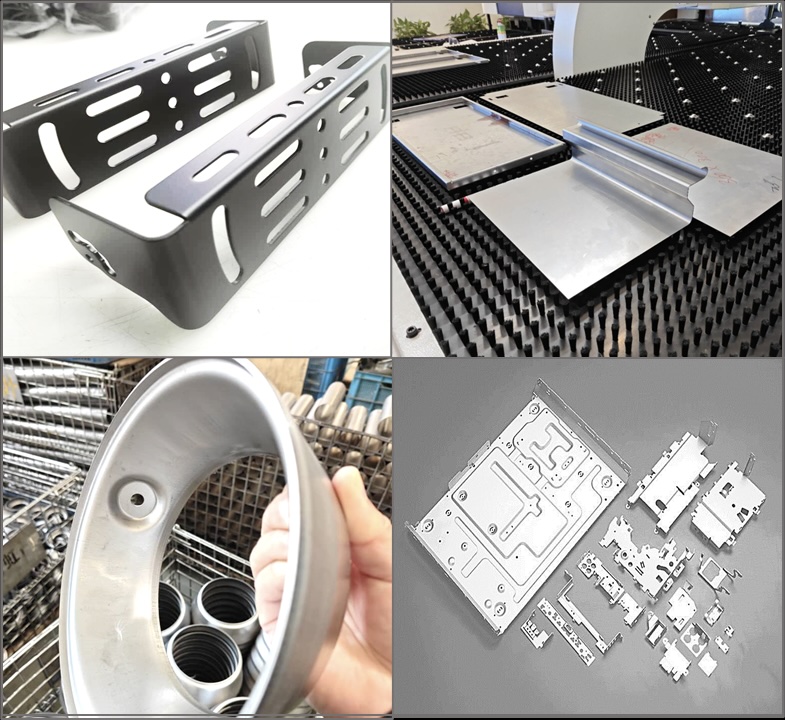

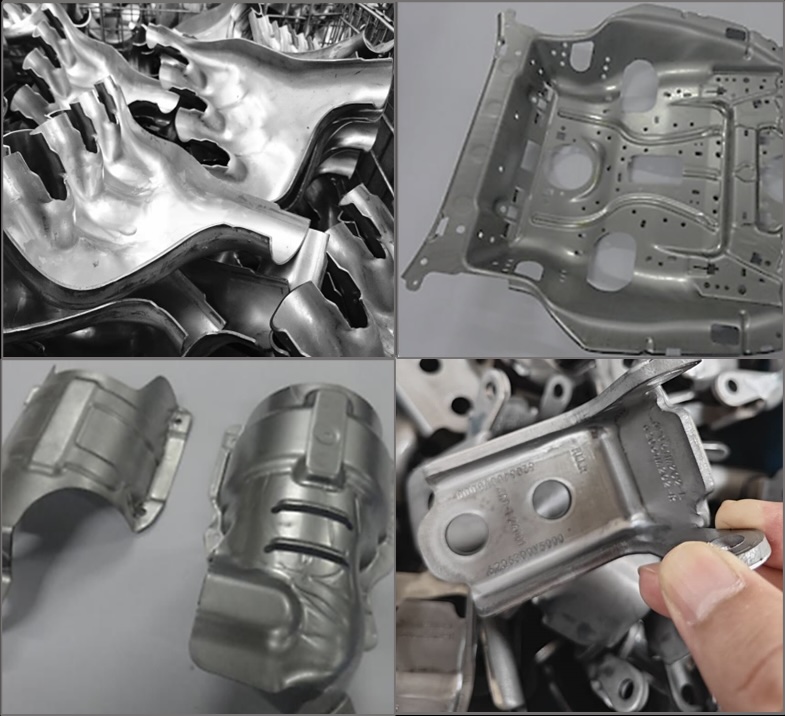

• Combination of different machineries such as high-speed high-tonnage and CNC machines

• Total 55 units of Japanese and branded stamping machines range from 30, 60, 80, 110, 150, 160, 200, 250, 400 and 600 tons, including high speed microstructure stamping machines

• 12 units of CNC laser cutting, turret punching, and bending machines

• We support different lot size production, especially High-Mix/Low-Volume Production.

• Serve wide range of industries and products, such as electronic components, sheet metal covers, equipment panels and fabricated structures.

• Provide necessary surface finishing treatment and secondary processes, such as paint coating, plating, silkscreen printing, hardening, fastener inserting, spot welding, and assembly.

• Quality assurance and digital quality control equipment ensure high quality products for customers.

• Our experienced engineers can understand and meet international clients’ quality standards and requirements.

• Our “Quality 1st Culture” always drive success of company, as well as gaining clients’ recognitions and satisfactions.

• Combination of using inhouse hard tool (stamping) and soft tool (sheet metal) capability benefit our clients in new product development, as well as maximize product development cost.

• We help customers in hard tool (stamping) and soft tool (bending) design and manufacturing.

• MIG, TIG, Laser Welding and Spot Welding

• OEM equipment building

• Industrial and machine structure fabrication

• Powder/paint coating, sand blasting

• Machine assembly, Field Application Testing (FAT)

• On-site machine installation and commissioning